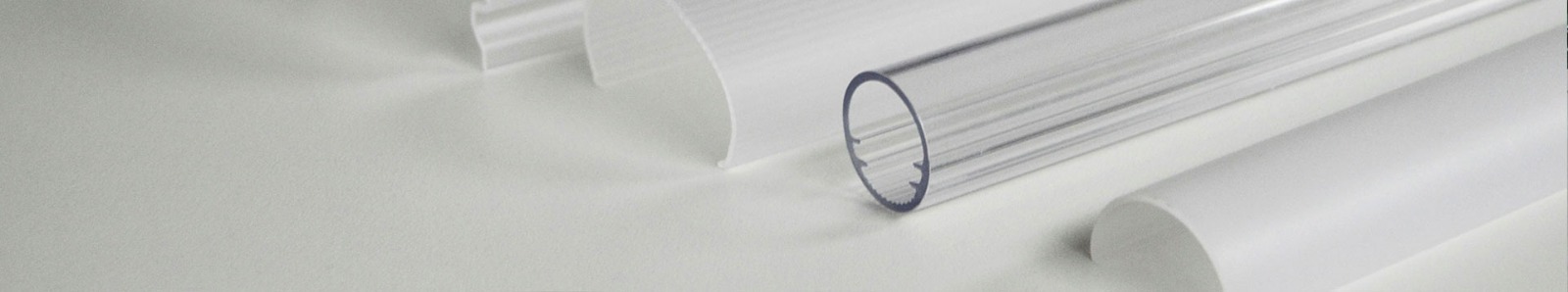

Extrusion

The plastic extrusion process involves melting plastic material, forcing it into a die to shape it into a continuous profile, and then cutting it to length. The process is a good choice for applications that require a final product with a constant cross-section. The low cost and high production rates make it a common manufacturing choice for products such as profiles, pipes, tubes, weather strips and gaskets.

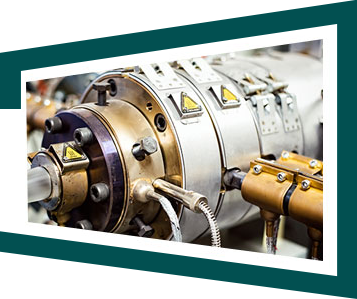

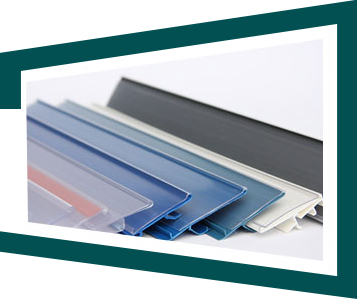

Co-Extrusion

Coextrusion is the process of pressing two or more materials through the same die to produce a single piece. When multiple plastics are combined, the result can yield properties distinct from those of a single material. Unlike the more simple monoextrusion, this process is more difficult, more complex equipments are needed and setup times are greater in proportion to the number of co-extruded materials.

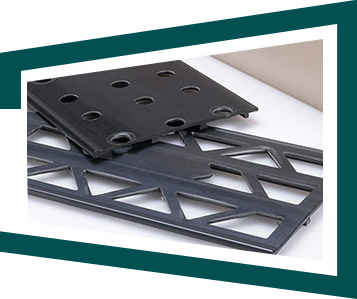

Punching

HAF Plastik is able to perform post-production operations upon request of our customers. We offer wide-range of punching solutions based on the needs of our customers.

Cutting

HAF Plastik offers full line of cutting services as part of our turnkey extruding and finishing services.

Adhesion

HAF Plastik offers various types of adhesion operations such as adhesive stripe, double-sided tape and protection film applications.

Welding

HAF Plastik offers simple and rapid solutions to its customers by post-production secondary operations such welding of gaskets.

Assembly

HAF Plastik offers custom assembly and packaging solutions according to your needs. Components can be assembled in sub-groups or fully assembled as the finished good.