EXTRUSION

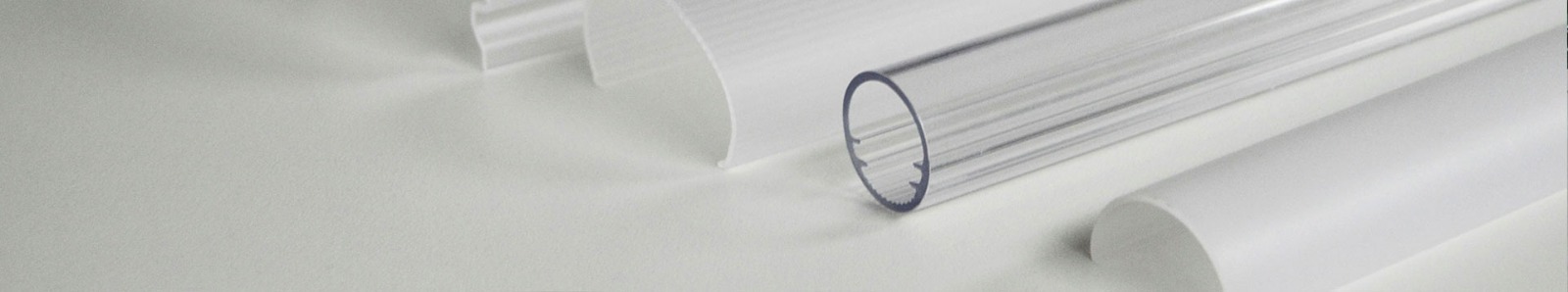

Plastic extruded profiles are created by melting raw plastic pellets and forming the melted material into a continuous profile. Plastic extrusion is a high-volume process used to manufacture a wide range of products including LED Light Diffusers, custom size tubing, shelf talkers, bumpers, conveyor covers, bumper strips, edge protectors, electrical insulator channels and more.

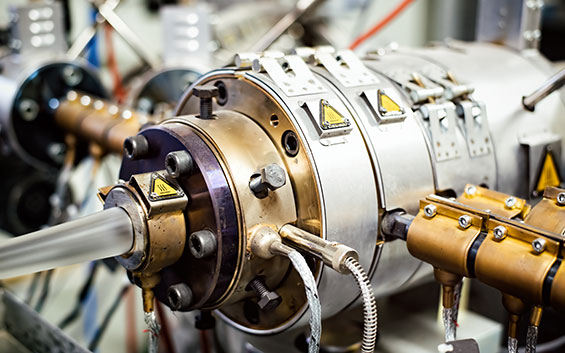

This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling.

Plastic extrusion is a green process with minimal waste and is recyclable. Our employees have years of experience allowing us to determine the optimal extrusion rates to produce your parts economically and efficiently.