CO-EXTRUSION

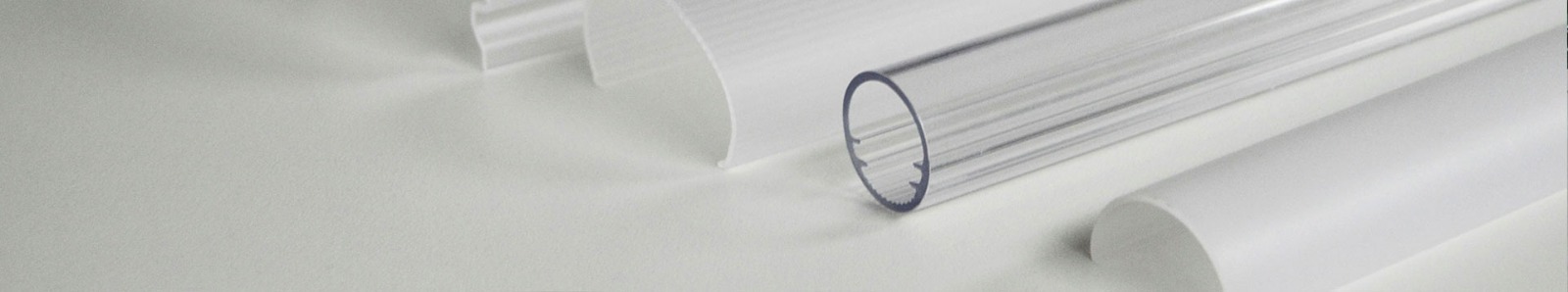

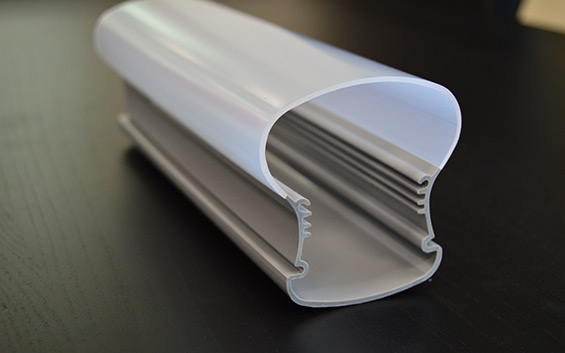

Co-extrusion is the process of pressing two or more materials through the same die to produce a single piece. When multiple plastics are combined, the result can yield properties distinct from those of a single material. Co-extrusion has opened up new frontiers in material engineering and addressed several previously difficult manufacturing needs.

Co-extrusion will enable you to achieve properties that could not otherwise be achieved. The process can help you save money by reducing the amount, and ultimately the cost of including more expensive compounds in the mix; and by allowing you to recycle scrap material, therefore lessening the amount of waste. Thus, co-extrusion is a useful manufacturing capability that’s good for your bottom line and good for the environment. Co-extrusion is ideal when the requirements of a design cannot be satisfied by a single material.